Crafting Excellence: Black Seed Oil Extraction Guide

Key Takeaways

| Key Aspect | Summary |

|---|---|

| Industry Relevance | Black seed oil is a hot commodity in the health, food, and skincare industries. |

| Focus of the Guide | Covers all steps: preparation, methods, scaling, and efficiency. |

| Ideal Audience | Geared toward beginners and experienced producers alike. |

| Ultimate Goal | Helps boost both yield and profitability in commercial production. |

Introduction

Have you ever wondered how black seed oil, prized for its amazing health benefits, is made? It’s not just about pressing seeds; there’s a whole process behind it. Whether you’re just starting or looking to refine your oil extraction business, you’ve come to the right place.

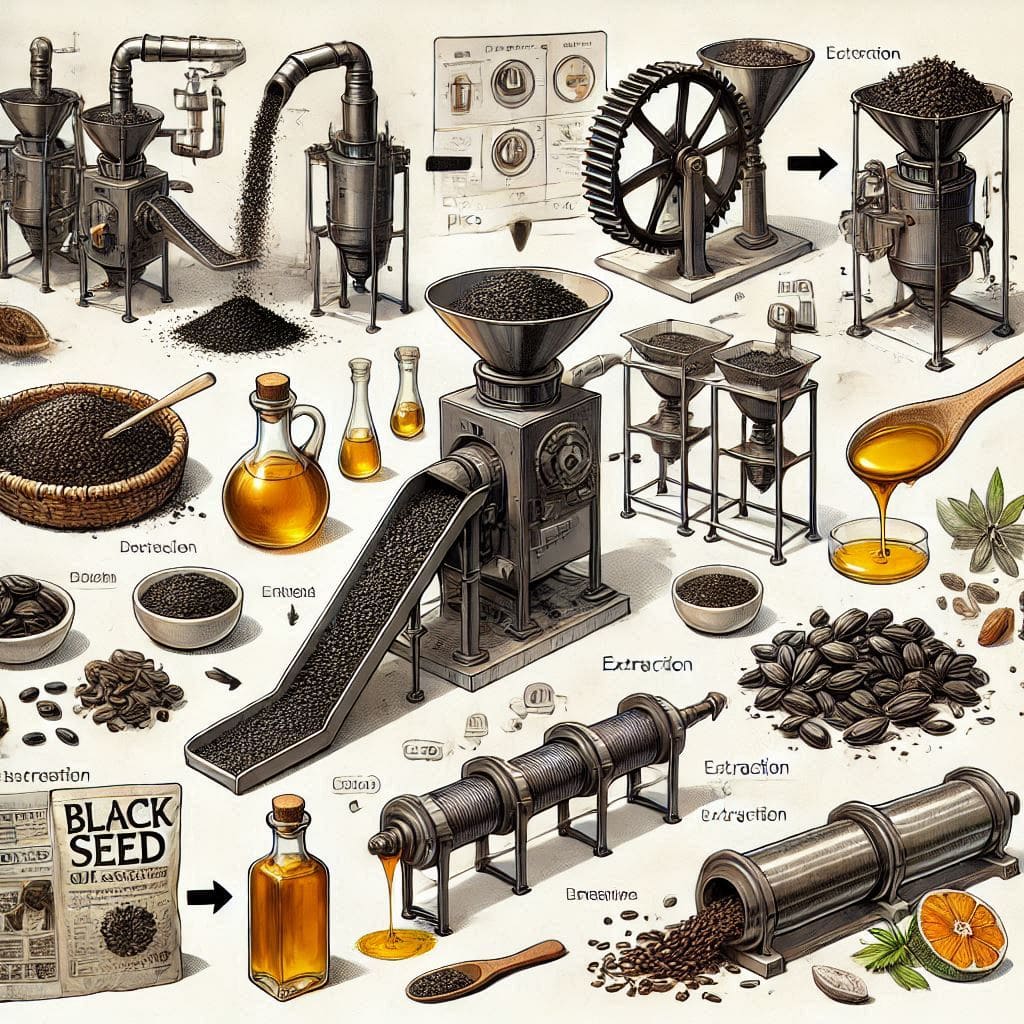

Black seed oil extraction

This guide walks you through the step-by-step process of black seed oil extraction while keeping quality and efficiency top-notch. From preparation to scaling up for commercial production, we’ll give you the tools to thrive in this growing industry.

Understanding the Basics

What is the best step-by-step process for extracting oil from black seeds?

The best method depends on your goals. For high-quality oil, cold-pressing is the way to go. It preserves the natural antioxidants and essential fatty acids in Nigella sativa seeds. Here’s the basic process:

- Harvest the seeds at peak maturity.

- Clean them thoroughly to remove dust or impurities.

- Use a cold-press machine to extract the oil slowly.

- Filter the oil to remove sediments.

How to extract black seed oil efficiently for commercial purposes

For commercial setups, efficiency is key. Automate cold-press machines with temperature controls to avoid overheating the oil. Stick to seeds with high oil content, and ensure proper storage to maintain freshness.

Black seed oil production: A detailed step-by-step guide

Let’s break it down further:

- Step 1: Cleaning: Remove debris, sticks, and dirt from raw seeds.

- Step 2: Drying: Dry the seeds in sunlight or a controlled environment.

- Step 3: Extraction: Feed the seeds into a mechanical press for oil extraction.

- Step 4: Filtration: Use a fine filter to ensure purity.

- Step 5: Packaging: Store the oil in airtight glass bottles to maintain its properties.

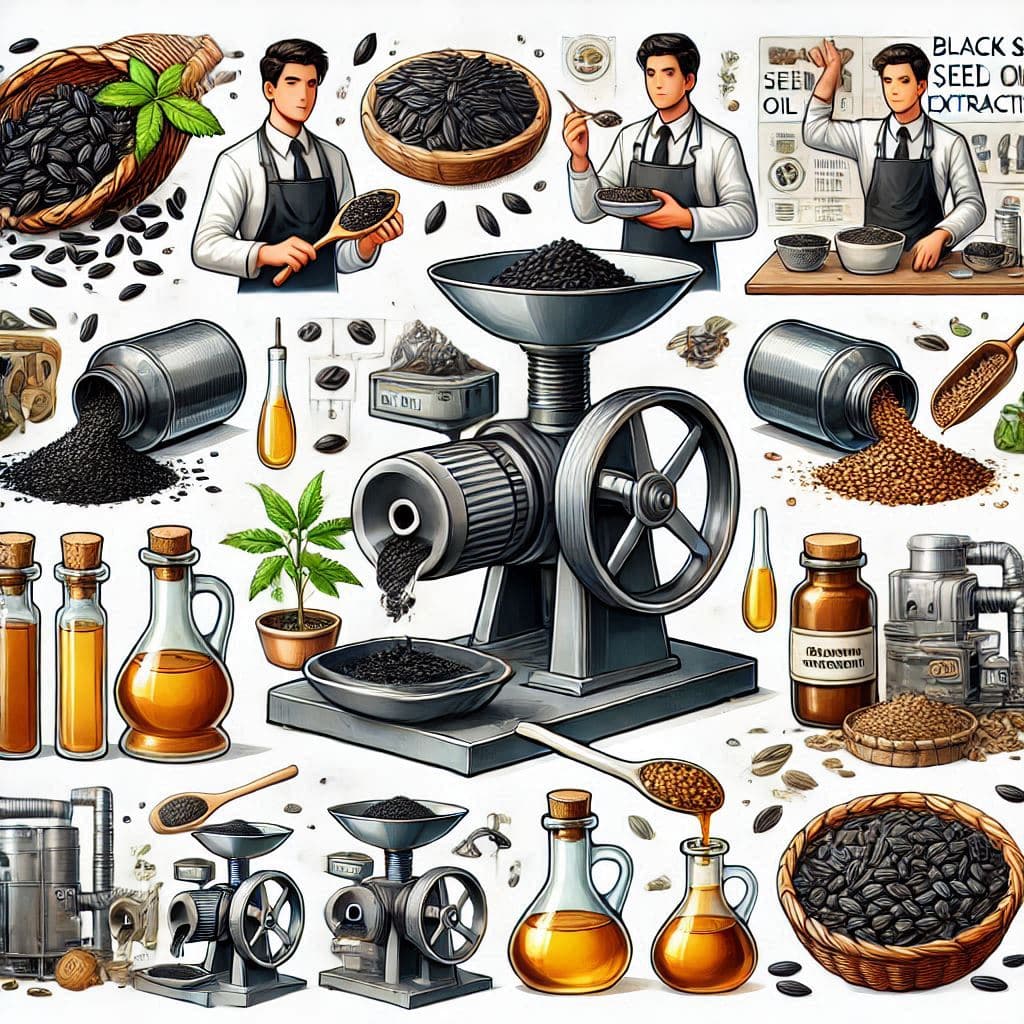

Complete guide to black seed oil extraction for beginners

If you’re new, start small. Use a manual or low-cost cold-press machine to experiment. Monitor every step to learn how different variables—like seed quality or pressing speed—impact the final product.

Preparation: Getting Ready for the Process

How to prepare black seeds for commercial oil extraction

Preparation is everything. Start by cleaning the seeds to remove foreign particles. Then, ensure the seeds are dry to prevent mold or moisture during storage.

What tools and machines are best for black seed oil extraction at scale?

Here’s the gear you’ll need:

Black seed oil extraction

- Cold-press machines: Opt for high-capacity models.

- Filtration systems: Keep your oil clean and ready for bottling.

- Temperature monitors: Ensures oil doesn’t overheat, preserving nutrients.

Equipment required for black seed oil extraction in commercial production

For large-scale setups, you’ll need:

- Pressing units for extraction.

- Oil filter presses for purity.

- Storage tanks for bulk quantities.

How to choose the best method for extracting black seed oil

Two main methods exist:

- Cold-pressing: Best for small to medium batches with high quality.

- Solvent extraction: Ideal for large-scale production but requires expertise.

Methods: Exploring Extraction Techniques

When it comes to extracting Nigella sativa oil, you have two main options:

- Cold-Pressing:

- Pros: Retains antioxidants, vitamins, and essential oils.

- Cons: Lower yields than chemical methods.

- Solvent Extraction:

- Pros: Efficient for commercial-scale operations.

- Cons: Chemical solvents might alter the oil’s natural properties.

Optimization: Ensuring Quality and Efficiency

| Optimization Focus | Strategy |

|---|---|

| Maximizing Yield | Use premium seeds and regularly maintain equipment. |

| Enhancing Quality | Stick to cold-pressing for nutrient retention. |

| Cost-Efficiency | Invest in durable, energy-efficient machinery. |

Techniques for increasing black seed oil production efficiency

- Automate wherever possible.

- Run quality control checks on seeds before processing.

- Optimize pressing speed to prevent overheating.

How to ensure quality during black seed oil extraction for commercial use

- Monitor extraction temperature—it should stay below 50°C (122°F) to retain nutrients.

- Test for impurities regularly using a purity analyzer.

Scaling Up: From Small-Scale to Large-Scale

Black seed oil extraction: From small-scale to commercial production

Scaling up doesn’t mean losing quality. As you expand, keep processes consistent and invest in high-capacity equipment.

Black seed oil extraction

How to scale up black seed oil extraction for commercial markets

- Buy bulk storage tanks to handle larger quantities.

- Upgrade to industrial-grade cold-press systems for efficiency.

Challenges and Solutions: Troubleshooting

What are the challenges in black seed oil commercial production?

- Seed Variability: Not all black seeds have the same oil content.

- High Initial Costs: Industrial equipment can be pricey.

- Market Saturation: The competition in health and wellness markets is growing.

How to improve black seed oil extraction efficiency in your business

- Train employees on how to handle sensitive equipment.

- Use data analytics to monitor yield trends and improve outcomes.

Conclusion

Making black seed oil for commercial production doesn’t have to be complicated. By following the right preparation methods, choosing the best extraction techniques, and focusing on quality, you can carve a profitable niche in this industry.

Ready to dive in? Equip your business with the best tools, stay consistent with your processes, and aim for excellence. The growing demand for Nigella sativa oil is your opportunity to shine!